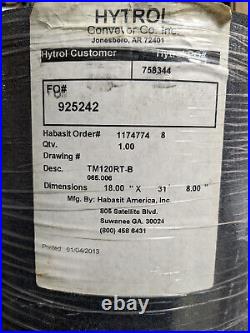

Habasit TM120RT-B Conveyor Belt 18 Width 31′ 8 Length Hytrol OEM

Habasit TM120RT-B Conveyor Belt 18″ Width 31′ 8″ Length Hytrol OEM. Trackmate General Purpose Belts. Trackmate 120 Rough Top. Main industry segments Distribution centers Applications Decline belt, Incline belt, Induction belt Special features Excellent tracking, Flexibility, High grip surface, Low noise applications suitable Product Construction / Design Conveying side material Polyvinylchloride (PVC) Conveying side surface Rough top Conveying side property Adhesive Conveying side color Black Traction layer (material) Polyester (PET) scrim Number of Fabrics 1 Pulley side material Polyester fabric (PET) impregnated with polyvinylchloride (PVC) Pulley side surface Fabric Pulley side color Black Product characteristics Antistatically equipped No Adhesive free joining method Yes Flammability No specific flammability prevention property Food suitability, FDA conformance No Food suitability, USDA recommendations No use intended Food suitability, EU conformance NoHeavy Conveyor Belts TM120RT-BProduct Data Sheet (Released) 06.12.2022 Technical data Thickness of belt 5.7 mm 0.22 inch Mass of belt (belt weight) 4.3 kg/m² 0.880 lb/sqft Tensile force for 1% elongation (k1% static) per unit of width (Habasit standard SOP3-155) 25 N/mm 145 lbf/in Tensile force for 1% elongation after relaxation (k1% relaxed) per unit of width (Habasit Standard SOP3-155 / EN ISO 21181) 9.4 N/mm 54 lbf/in Min. Operating temperature admissible (continuous) -23 °C -10 °F Max. Operating temperature admissible (continuous) 70 °C 158 °F Coefficient of friction (pulley side / steel driving pulley) 0.20 – Coefficient of friction (pulley side / driving pulley with friction cover) 0.35 – Coefficient of friction (pulley side / pickled steel slider bed) 0.25 – Coefficient of friction (pulley side / phenolic resin slider bed) 0.20 – Coefficient of friction (pulley side / stainless steel slider bed) 0.20 – Seamless manufacturing width 1829 mm 72.00 inch On request other seamless manufacturing width 1524 mm 60 inch Joining related properties Joining method Clipper #1 Master joining method for standard applications Flexproof 10 x 80 Optional joining method Link to JDS: Joining method Clipper #1 Flexproof 10 x 80 Pulley diameter (minimum) mm inch 71 2.80 71 2.80 Pulley diameter minimum with counter flection mm inch 102 4.00 102 4.00 Admissible tensile force per unit of width N/mm lbf/in 16 91 Admissible tensile force per unit of width at max. Operating temperature N/mm lbf/in 14 80 Slider bed suitable Yes Yes Carrying rollers suitable Yes Yes Troughed installation suitable No No Powerturns / curved installations No No Knife-edge (nosebar) suitable No No Low noise applications Yes Yes Metal detector suitable Yes Yes All data are approximate values under standard climatic conditions: 23°C/73°F, 50% relative humidity (DIN 50005/ISO 554). Limited representative testing based on a standard configuration is carried out to estimate minimum pulley diameters. Please contact Habasit for specific guidance regarding non-standard applications, including, but not exclusively, when profiles or cleats are used, or if the belt working temperature is close to the limits listed in this document. Should you still need a calculation: please ask Habasit. Recommendation Do not exceed 1% elongation, Do not go below initial elongation (epsilon) 0.3%, Install the slack belt and tension until running perfectly under the full belt load Protect belts from sunlight/UV-radiation/dust and dirt. Store spare belts in a cool and dry place and if possible in their original packaging. SAFETY WARNINGS SHOULD BE READ CAREFULLY AND ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Habasit catalogue as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness, accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to re-assessments and modifications within a short period of time and without prior notice. EXCEPT AS EXPLICITLY WARRANTED BY HABASIT, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED “AS IS”. BECAUSE CONDITIONS OF USE IN INDUSTRIAL APPLICATION ARE OUTSIDE OF HABASIT’S CONTROL, HABASIT DOES NOT ASSUME ANY LIABILITY CONCERNING THE SUITABILITY AND PROCESS ABILITY OF THE PRODUCTS, INCLUDING INDICATIONS ON PROCESS RESULTS AND OUTPUT. Heavy Conveyor Belts TM120RT-BProduct Data Sheet (Released) 06.12.2022.